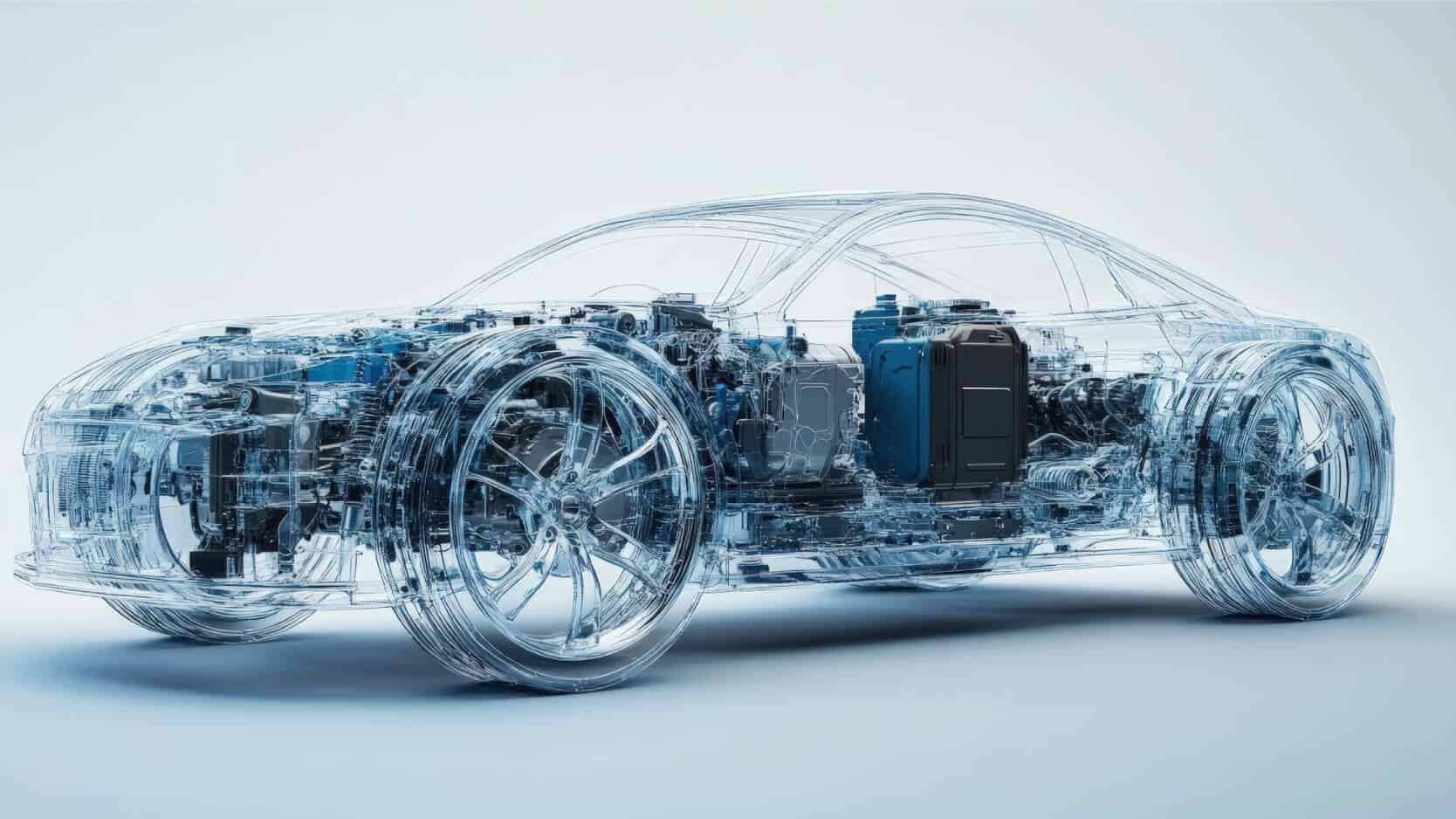

مكونات السيارات الكهربائية والوقود

Sep 04 , 2025اِصطِلاحِيّ نظافة تقتيش حل ل مكونات السيارات الكهربائية والوقود

1. لماذا نحتاج اِصطِلاحِيّ نظافة تقتيش ل الوقود والسيارات الكهربائية عنصر

1.1 منع تلوث أجزاء السيارات

يمكن أن تؤدي الشوائب مثل الحطام المعدني والزيت والجسيمات الكاشطة المتبقية على المكونات أو داخلها إلى التآكل المتسارع للأجزاء المجمعة، وتعطل المكونات الدقيقة، وفشل الختم.

1.2 منع تلوث الأنظمة الحرجة

- نظام الوقود: يمكن للشوائب أن تسد فلاتر الوقود والحاقنات، مما يتسبب في انخفاض قوة المحرك، أو عدم استقرار سرعة الخمول، أو حتى التوقف.

- نظام التزييت: يمكن للجسيمات الموجودة في زيت المحرك أن تؤدي إلى تفاقم التآكل الداخلي للمحرك وتقصير عمر الخدمة.

- نظام الفرامل: يمكن أن تتسبب الشوائب الموجودة في خطوط الفرامل أو الفرجار في تأخر الفرامل، وإصدار صرير غير عادي، وفي الحالات الشديدة، فشل الفرامل.

- الأنظمة الإلكترونية: يمكن أن يؤدي تلوث المستشعرات وموصلات حزمة الأسلاك بالزيت أو الغبار إلى فشل نقل الإشارة، مما يؤثر على وظائف مثل القيادة الذاتية ونظام منع انغلاق المكابح (ABS).

1.3 منع التلوث أثناء تجميع السيارة

- بيئة التجميع: تأكد من نظافة هواء الورشة (على سبيل المثال، مستوى الغبار) ونظافة سطح العمل لمنع دخول الغبار والألياف إلى هيكل السيارة أو مكوناتها.

- أدوات التجميع: يمكن للمفاتيح والمشابك والأدوات الأخرى التي تحتوي على الزيت أو برادة المعدن أن تلوث المكونات أثناء التشغيل.

- الخدمات اللوجستية: يمكن أن تؤدي العبوات التالفة أثناء النقل والتخزين إلى إدخال الملوثات بسهولة (مثل مياه الأمطار والطين والرمل).

2. معايير الاختبار ل اِصطِلاحِيّ نظافة التفتيش في مكونات السيارات الكهربائية والوقود

• يتوافق مع معايير جمعية صناعة السيارات الألمانية (VDA) VDA PPA 2020 (الطبعة السادسة).

• مواصفات VDA 19.1/VDA 19.2: يجب على جميع الموردين من المستوى 1 والمستوى 2 والمستوى 3 الامتثال للمعايير مثل VW 01134 وBMW QV11111 وMercedes-Benz TRL، والتي تلتزم بها JYBO CleanTech بشكل صارم.

• يتوافق مع المعايير الدولية VDA 19 و ISO 16232.

3. JYBO CleanTech اِصطِلاحِيّ نظافة حلول التفتيش ل مكونات السيارات الكهربائية والوقود

قطع غيار سي سي إل نظافة ج أبينيت

- طرق التنظيف الاختيارية: ضغط الشطف ، الموجات فوق الصوتية، شطف التروية ، و تنظيف الاهتزاز

- ضغط الشطف- يدوي التشغيل باستخدام الفوهة تأكد من عدم وجود جزيئات متبقية في الزوايا

- ت النظافة الفنية يتم إجراء عملية الاستخراج في الفئة 100 غرفة العمليات

- متوافق مع مجموعة متنوعة من مكونات السيارات نظافة

- مخصص معدات تنظيف مكونات التنظيف متاحة لتلبية جميع متطلبات الاختبار

ج أ 53 مليونًا تكنيكا l نظام تحليل النظافة

- يحلل التلوث الجسيمي النوع والحجم والكمية لتحديد ما إذا كانت ستؤثر على تشغيل السيارة

- يتم إنشاء نقرة واحدة تلوث تقرير يقدم معلومات كاملة ج جزيئات الملوثات أ التحليل

- مراقبة بيانات الجسيمات على المدى الطويل لتحسين عمليات الإنتاج

- تحليل جزيئات النظافة بشكل آلي بالكامل، مما يلغي التدخل اليدوي

- جسيم أ التحليل س النظام مع ح كفاءة التحليل العالية